|

|

Conduct Feller Buncher Operations

Unit FPIHAR3207B:

Conduct Feller Buncher Operations

Forest Operations > Conduct Feller Buncher Operations > Feller Bunch At Work

Forest Operations > Conduct Feller Buncher Operations > Feller Bunch At Work

Feller Bunch At Work

The next group of pictures will show the cutting of blue gum trees, bunching them in the head, and placing the trees on the ground in a workable system for the skidder operator.

Fig 1 First tree

In the first picture, figure (1) the operator has estimated the felling head will hold three trees, and will position the machine three trees in from where the bunched ones will be laid down for the skidder operator.

The feller buncher is positioned with the head tilted slightly forward (about 5o). This will push the top of the tree away slightly preventing saw jam.

The first tree is cut off and held with the clamp arms, and then the machine is moved back towards the second tree in a fluent but swift motion.

Fig 2 Second tree

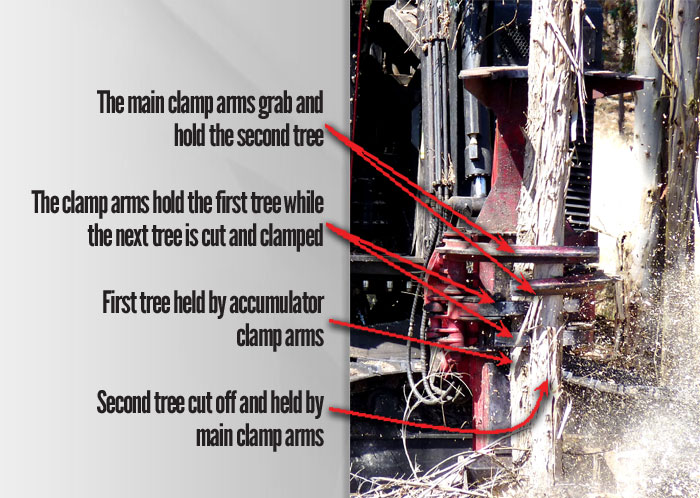

When the feller buncher is in position, you open the main clamp arms while holding the first tree with the secondary clamp arms (see Fig. 2 & 3).

Then cut and hold the second tree, lifting the head approximately 1 ft (30cm) off the ground and moving the machine to the third tree smoothly and quickly.

Keeping the head low to the ground when moving to the next tree will ensure the machine remains stable to allow for being able to efficiently place the head at the base of the next tree.

Fig 3 Close up of second tree being cut

Fig 4 Third tree

The buncher is then moved to the third tree (see Fig. 4) which will be the capacity for the felling head with trees of this size.

Once the tree is cut off and clamped, the head is lifted approximately 1ft (30cm) off the ground. The machine is then moved to the location ready to bunch trees for the skidder.

Video 1 - TigerCat LX870C TigerCat feller buncher cutting in alpine country

Accumulated tree placement

Once the feller buncher has been moved into position, with the trees in the head, you will proceed to accurately lay the trees with the already bunched trees on the ground (Fig. 5).

Fig 5 The three trees being placed and bunched with other trees

Head tilt function

As you approach the bunched trees on the ground, the machine is slewed into position, lining up the accumulated trees in the head with the trees on the ground.

The felling head is tilted over, pushing the trees away from the machine and the clamp arms are opened (Fig. 6).

This system of bunching trees will continue until the required amounts of trees are bunched for the skidder to snig to the landing site.

Fig 6

Cutting disc

The disc saw (also known as a hot saw) is high speed and aggressive but an efficient tree cutting piece of equipment. The cutting teeth are made of high grade metal called tungsten (Fig. 7) which can withstand huge amounts of pressure, wear and endurance.

Fig 7

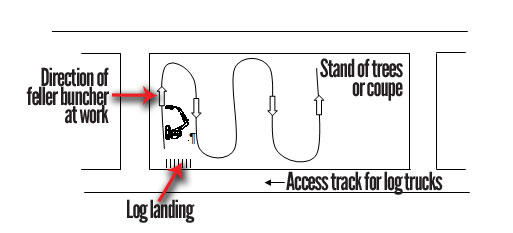

Production thinning work patterns

Felling patterns in thinning operations are often more varied because of the residual stand and the harvesting system used.

For tree length extraction, many of the same principles for clear felling apply. Felling normally progresses away from landing sites or road way and fire breaks (Fig. 8).

If the feller buncher is harvesting trees for a mechanical processor and for extraction by a forwarder, the felling strips may progress away from, and then back towards the log landing or road edge.

The trees are felled and bunched at right angles to the travel direction of the machines and processed into specific products on the opposite side of the track in readiness for extraction by the forwarder.

Fig 8