|

Forest Operations > Operational Hazards > Hydraulic / Air Safety

Forest Operations > Operational Hazards > Hydraulic / Air Safety

Hydraulic / Air Safety

As part of your job in a forest operation there are a range of machines and equipment that are operated using hydraulic systems that you may have to work with or come into contact with.

Your employer should have safety procedures in place for the times that you do have to undertake any maintenance and repairs involving hydraulic parts or handling of substances.

It is your responsibility to make sure that you know and follow the procedures that have been put in place; not only for your safety but for the safety of other people you have to work with.

You should try to avoid excessive contact with hydraulic oils. Remember: high temperatures and high pressures are present, and both can cause serious injury.

Skin ailments (allergies and irritations) can result from too much contact with hydraulic oil.

Cuts and puncture wounds can be caused from exposed wire on hydraulic hoses and damaged components.

When changing a hydraulic hose or component always ground the attachment, neutralise the levers and turn off the machine.

Release the hydraulic pressure from the system and wear all the appropriate safety equipment (petroleum resistant gloves and safety glasses).

Most importantly, never check for hydraulic leaks on hoses or components such as rams, hydraulic pumps or motors and valve banks, while the machine is running and full hydraulic pressure is present in the system.

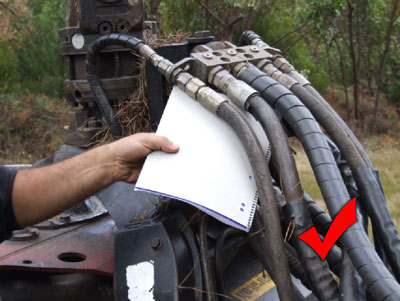

When checking for oil leaks, use a piece of cardboard or wood (Fig 29a), never use your hands to search for suspected leaks (Fig 29b).

If hydraulic oil enters your flesh it could result in a serious injury called high pressure injection injury.

If you are injured by escaping hydraulic oil see a doctor at once.

Serious infection or reaction can develop if medical treatment is not administered immediately.

Fig 29a Always use a piece of board or cardboard. |

Fig 29b Never use your hands to check hydraulic hoses leaks |

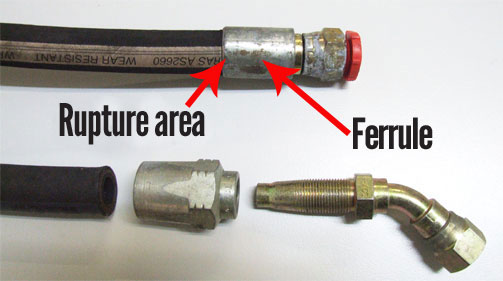

The following example (Fig 30) will show you what can occur when hydraulic equipment fails causing a pinprick intrusion wound to your hand.

A warning to us all:

Hydraulic oil Injection injury

- Hydraulic Fluid in use was a Mineral Oil – Unknown at present.

- Pressure of fluid was 630Bar (Approx 9,150 psi). Most modern forest machine hydraulic pressures are approximately (4000 to 5000 psi).

- Equipment in use was a pair scissor cutters used at road traffic accidents to release occupants.

- Location of the accident was at a Fire Service Training Ground.

- Risk Assessments were in place and all appropriate PPE was worn.

Fig 30

Events

- Training session under controlled conditions within the fire brigade training grounds;

- Patient was cutting through sample vehicle using Jaws of Life;

- Normal practise was for hydraulic hose to be run over operators shoulder to the tool;

- Hose ruptured at ferrule area resulting in release of high pressure fluid through PPE (leather gauntlets figure 8c in OH&S safety equipment) to patient’s hand (see Fig 31).

Fig 31

What Happened Next

- The patient went to Accident & Emergency Hospital Ward and original diagnosis was “Keep clean and rest”.

- By chance a specialist observed and intervened.

- Mineral Oil had already started to “eat away” fatty tissues in the hand and began travelling up the arm.

- The patient had five operations to cut away oil deposits and was on his last chance before losing his arm (Fig 32). It was successful.

- Wound could not be sutured due to tissue damage by the oil, so it gradually closed over, after a period of weeks.

Fig 32 Hand has been cut open by doctor to remove hydraulic oil.

Results

- The patient was in due course medically discharged from fire brigade and is severely disabled in this hand.

- Hydraulic Fluid in use has been changed to “Aero Shell Fluid 4”.

- Fire Brigade has passed the results of the incident on to other Brigades

- Litigation is in place.

- Patient to Brigade;

- Brigade to Equipment Manufacturers;

- The Patient awaits final outcome;

- Timescale: 2 years and counting.

Compressed Air

Compressed air equipment (Fig 33) is to be found on almost every service vehicle on a forest operation.

Fig 33 Portable Air Compressor

In the dry dusty months of the year, compressed air is one of the everyday features of servicing machines.

There are a number of ways in which compressed air can be used safely.

A compressed air gun should not be used to clean bark and dirt off machines.

A shovel, fire rake, and then a broom should be used.

Compressed air should be used with care and respect when blowing down machine components such as air cleaners, radiators, windows and cabins.

When blowing down machine components, particles of dirt and sharp fragments are thrown up into the air.

Fig 34 Safe use of compressed air.

The pressure necessary to remove the particles from the machine is strong enough to blow them into the eyes, ears, or the skin of people nearby.

Never point a compressed air gun at yourself, or another person.

When disconnecting air lines, turn the air tap off.

Check compressor and air tools regularly.

Use the correct PPE at all times to avoid serious injuries or death (Fig 34).

Never dust yourself or someone else down with compressed air.

This can lead to:

- Injury to the eyes, ears, nostrils and rectum;

- Air entering a scratch or puncture in the skin causing the limb or effected part to swell to alarming proportions accompanied by severe pain;

- Air being forced into the bloodstream, making its way into the small blood vessels of the brain, bursting the vessels and causing death.

Fooling around with air guns may end in severe injury or death.

Refer to the web for the short film clip on compressed Air Safety.

Self Help Activity 15, Hydraulic Safety

Download the activity by clicking the icon above. When completed please submit via the LMS or directly to your trainer.

Self Help Activity 16, Air Safety

Download the activity by clicking the icon above. When completed please submit via the LMS or directly to your trainer.